For SpaceShipOne, reaching space takes three things: a pilot, a spacecraft and enough propellant to rocket away from Earth.

But the fuel in SpaceShipOne's tank is about as exotic as the spacecraft's design. SpaceShipOne, set to be the first nongovernmental crewed vehicle to reach space, uses a combination of rubber and nitrous oxide — also known as laughing gas — as the powerhouse for test flights and an anticipated suborbital spaceshot set for June 21.

"These are all state-of-the-art technologies," Jim Benson, founding chairman and chief executive of SpaceDev, said of SpaceShipOne's fuel process. "It's a very stable and nontoxic system."

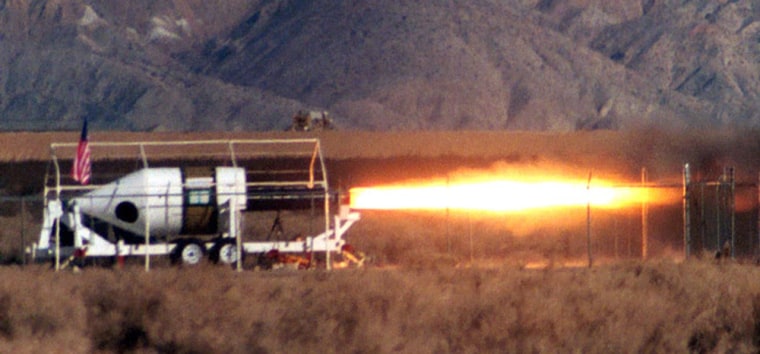

Based in Poway, Calif., SpaceDev is responsible for refueling SpaceShipOne after each flight as well as providing crucial elements of its hybrid rocket engine, a cross between traditional liquid and solid rocket motors.

SpaceShipOne was designed by aerospace veteran Burt Rutan and his Mojave, Calif.-based firm, Scaled Composites. The craft represents one of 26 teams vying for the Ansari X Prize competition to build a private-sector vehicle capable of transporting three people 62 miles (100 kilometers) above Earth twice in two weeks, with the winner snagging a $10 million purse.

A rubbery fuel

Rocket propellants come in two parts, fuel and oxidizer, which work together to keep an engine burning.

SpaceShipOne burns a material called hydroxy-terminated polybutadiene, or HTPB — a common ingredient in tire rubber — as fuel, with nitrous oxide serving as the oxidizer. According to press statements by Scaled, the combination was chosen for SpaceShipOne after a lengthy study into potential engine systems.

The propellant comes together in an 8-foot (2.4-meter) combustion chamber, where the liquid oxidizer is converted into a gas, then ignited by small pyros to start the engine. SpaceShipOne pilots can shut down the vehicle's engine by closing a valve through which nitrous oxide enters the fuel chamber.

"There has to be a way to shut off the motor," Benson said. "And we've done that in every flight, each one with more propellant than the last."

Less toxic, burns great

In conventional rockets, propellant can be pre-mixed — as in the solid rocket boosters used by NASA's space shuttle — or sit in tanks that are filled just prior to launch, like liquid oxygen and hydrogen rockets. In both engine configurations, the propellants are highly volatile and can be toxic to handle.

"The fact that the oxidizer and fuel are not molecularly mixed in these [hybrid] engines makes them nonexplosive," explained Greg Zilliac, a hybrid-engine researcher at NASA's Ames Research Center in Moffett Field, Calif. "We've actually shipped fuel grains by UPS in the past."

The HTPB fuel developed by SpaceDev is nonvolatile, making it easier and safer to store than other materials. It is readily available in 5-gallon (19-liter) drums and inexpensive, Benson said. Nitrous oxide's tendency to be self-pressurizing also does away with the need for complicated pumps to push it into SpaceShipOne's combustion chamber, he added.

The system also touts a somewhat cleaner way to reach space. Its byproducts — water vapor, carbon dioxide, carbon monoxide and nitrogen — are preferable to the waste produced by the shuttle's solid rocket boosters, which burn ammonium perchlorate and aluminum.

Loading a hybrid engine

SpaceShipOne's engine, a composite structure designed by Scaled, consists primarily of two parts: a tank of nitrous oxide and a cylinder with the HTPB fuel. Both SpaceDev and Miami-based Environmental Aeroscience Corp. contributed components of the engine.

To prepare SpaceShipOne for flight, rubber fuel is poured into a fuel casing and allowed to harden in a pielike mold before being installed into the spacecraft's aft fuselage. After a test flight, ground crews need only replace the fuel casing and attached nozzle, then top off the nitrous oxide tank to ready the craft for the next trip.

However, Zilliac, who works with researchers at Stanford University on paraffin-based hybrid engine fuels, questions whether SpaceDev and Scaled are really using a pure hybrid. "They've been sort of close-mouthed about the formulation of their fuel, like any other commercial project."

Rubber-based hybrid engines tend to burn at slower rates compared to solid materials, which can affect the final amount of thrust an engine can produce, Zilliac said. Some of that burn reduction can be recovered by SpaceDev's use of pielike ports for its solid fuel, but additives in the solid fuel could also boost performance.

Benson said that although SpaceDev's HTPB mixture is a trade secret, it does include some non-HTPB material. Lower performance is a downside to hybrid engine systems in general, which is why SpaceDev is developing a high-performance version to rival some conventionally propelled rockets, he added.

Engines of the future

Zilliac said the success of SpaceShipOne could increase general interest in hybrid engines, especially for eventual use in space where the hydrazine is currently the prime propellant.

"You have to choose applications where the performance is relevant," Zilliac said, adding that hydrazine is highly toxic and explosive, and the logistics of loading a spacecraft with the fuel are difficult. There, hybrid fuels could be a viable alternative, he said.

SpaceDev has already begun an in-space effort with the Air Force Research Laboratory to develop a second stage engine to push small payloads around Earth, moving them to higher and lower orbits as needed. The company is also developing its Streaker launch vehicle to use hybrid engines as well.