With a big boost from the government, algae is making headway as a potential replacement for some of the 18 million barrels of crude oil used daily nationwide.

Not only has the federal government invested heavily in the emerging biofuel, but the military has stepped up as a potential customer. Algae biofuel, while still experimental, also is attracting the attention of big oil companies and commercial users including airlines and manufacturers.

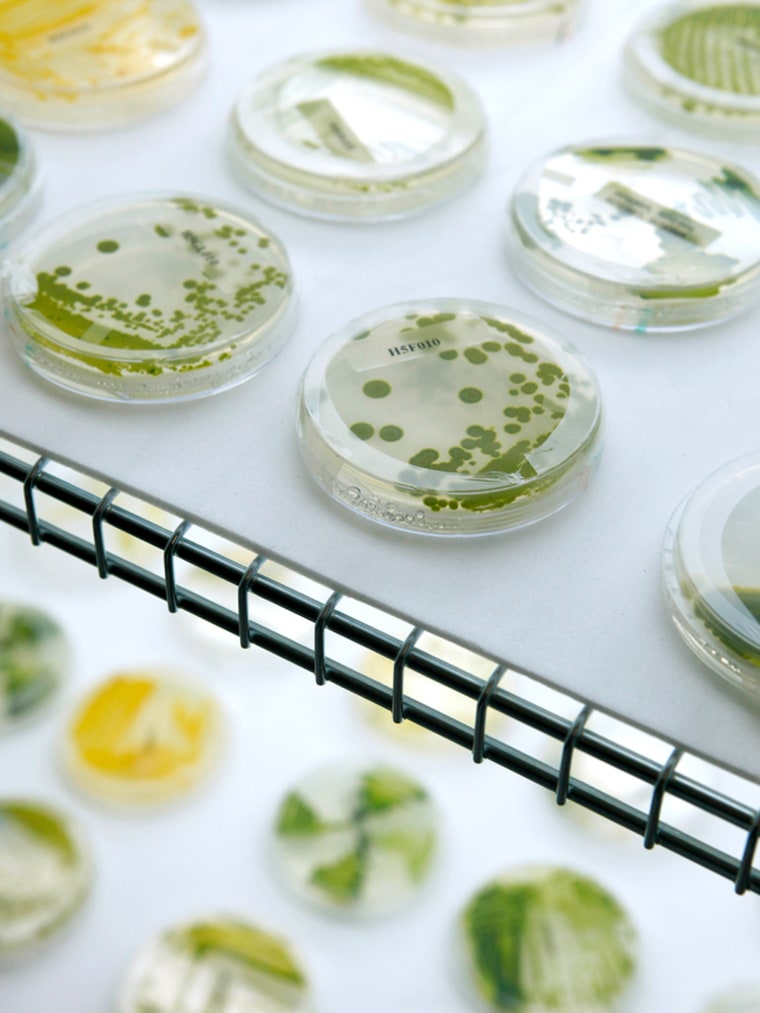

Algae biofuel is an experimental source of renewable energy that’s produced when algae produce a substance that can be harvested and processed into crude oil. The crude can then be processed in traditional oil refineries and converted into fuels for transportation, such as diesel, gasoline or jet fuel, or they can be used to replace the oils in soaps, foods and pharmaceuticals.

Algae use less overall carbon than fossil fuels because the plants absorb carbon as they grow and release it when their fuels are burnt, rather than just releasing carbon during use, as is the case with petroleum-based fuels. And of course algae can be grown domestically, reducing the amount of petroleum we need to import.

The clearest example of how far algal fuels have come was on display in late October when the Navy tested a river patrol boat that was powered by algae biodiesel. The small ship was the first sea vessel the Navy has tested as a part of its effort to sail a “Great Green Fleet” in 2016, and to source half of its energy from renewable fuels by 2020.

Tom Hicks, deputy assistant secretary of the Navy for energy, says that those dates are based, in large part, on what the Navy expects the biofuels industry can achieve. "The goals that we've laid out for ourselves tie into where industry is headed," he says."

Sapphire Energy, a San Diego-based company, grows algae using unfiltered, brackish water on land that was otherwise unused. The company's pilot facility, in the southern New Mexico desert, contains a series of long, outdoor ponds where the algae has access to abundant sunlight, which it converts into energy.

Sapphire’s desert construction is common for the industry. Many algae start-ups have been built in the sunny southern United States and in Hawaii, where importing fuel is costly, says Richard Sayre of the Donald Danforth Plant Science Center in St. Louis.

Kristina Burow, co-founder of Sapphire Energy, says the company “spent a considerable amount of time and effort to make our algal strains agriculture-ready, so that they can grow in a wild setting. And New Mexico is plenty wild.”

With the help of over $100 million in grants and loan guarantees from the departments of Energy and Agriculture, Sapphire broke ground this year on a new, 300-acre facility. The complex will allow the company to produce larger batches of the fuel, and to test plans for self-contained production facilities.

Labor costs for the young biofuel industry can be particularly high because of the need for a diverse team of biologists, geneticists and engineers, similar to the way an established oil company would employ specialists in geology and drilling technologies.

For biofuel companies, bringing down the cost of production is among the biggest challenges they face, and they are constantly searching for ways to save money and improve output.

In South San Francisco, another startup, Solazyme, has tried to cut costs and speed the timeline by growing algae in fermentation tanks, feeding the microbes sugars rather than sunlight. This avoids the need to test the construction of expensive new facilities.

Algae can be fed anything “from forest residue, like wood chips, to prairie grasses, like switch grass," said Jonathan Wolfson, CEO of Solazyme.

Solazyme’s goal is to produce algae-based crude oils that cost between $60 and $80 per barrel, which would make it competitive with oil, currently trading for about $80 a barrel.

Solazyme has partnered with oil giant Chevron, giving the company access to additional capital and to refining facilities in Pennsylvania.

As Wolfson explains that, after “many years and many millions of dollars of investment,” Solzyme has been able to bring down its costs, Wolfson says. But ”ultimately, we still need a dedicated, appropriately sized plant to hit the cost structure.”

Wolfson says that Solazyme, which was founded in 2003, is on track to deliver more than 100,000 barrels of oil this year, most of which will go to the Navy. He says that the coordination between the departments of Energy, Agriculture and Defense helps companies like his cross the “chasm of death” from the initial raising of capital to having a market-ready product.

Despite some early successes, the algae fuel industry is still a few years from commercial-scale production. Steve Chalk, acting deputy assistant secretary of energy for renewable energy, the government, says he expects to see commercial production increase over the next five years, with algal biofuels reaching the commercial market in five to ten years.

Potential customers already are testing the product. Last year Continental Airlines tested a biofuel blend that used algae from Sapphire Energy. Boeing has also tested algal biofuels, and plans to fly another test in 2011 using an algal biofuel produced in China.